Account Holder? Login for Wholesale Pricing

Call 1-800-661-9891

Mon-Fri 8am-8pm | Sat 9am-6pm (EST)

Call 1-800-661-9891

Mon-Fri 8am-8pm | Sat 9am-6pm (EST)

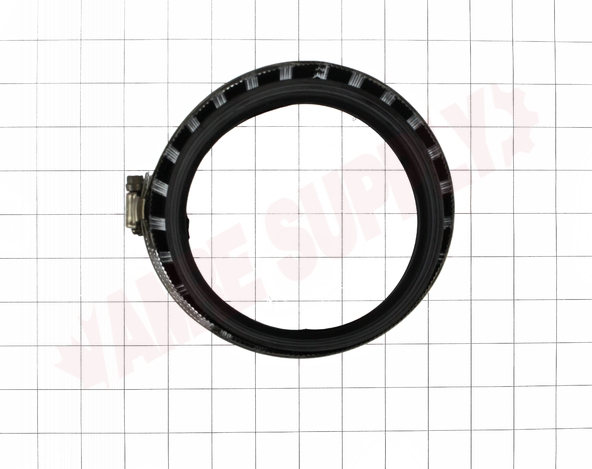

Fernco 5" No Hub Coupling

No Longer Available

This part is no longer available from the manufacturer.

| SKU: | NH-55 |

No Hub Coupling- Engineered to connect no-hub cast iron pipe.

Choose the No-Hub Coupling with the patented shield design that provides maximum transfer of pressure from the clamps - to the gasket - to the pipe. Engineered to connect no-hub cast iron pipe in applications replacing the less-efficient hub and spigot.

Standard Duty No-Hub

Size: 5"

Clamps Per Coupling: 4

Install torque (Inch Pounds): 60

5/16" hex-head screw applies 60 in.-lbs. of installation torque to the band/shield assembly.

Standard No-Hub Couplings conform to CISPI 310. Couplings comply with ASTM C 1277. Gaskets are made from an elastomeric compound that meets the requirements of ASTM C 564.

Patented Bi-Directional Shield Design- The shield will adjust to variations in diameters and circumferences of the pipes being joined, thereby eliminating leak paths. The patented, bi-directional corrugations exert sealing pressure in both parallel and transverse patterns on the gasket and pipe, providing a positive, reliable seal.

Specially Beaded Gasket- Made of an elastomeric compound that meets the requirements of ASTM C564 and features a series of strategically positioned grooves and beads. When tightened, the shield mates with these grooves and beads to exert exceptional sealing pressure and holding power to prevent "pull out" failures.

Interlocking Clamp Design- The clamps feature a one-piece screw housing that mechanically interlocks the housing to the band. This one-piece housing design eliminates leak paths that can occur in staked or welded clamps.

Floating Eyelet Design- Floating eyelets fasten the clamps to the shield, allowing the clamp band and shield to move independently. This freedom prevents the shield from crimping during tightening, which can lead to leakage later on.

Similar Products Found In